Review of knoop hardness testing

In production it is important to determine the hardness of an object or a material as it helps us in quality control by determining the tensile strength, resistance to impact and whether it has the ability to function as designed. Hardness being the ability of a material to withstand indentation is a characteristic of a material and can be determined using different tests which vary depending with the material being tested. Knoop hardness testing also known as micro hardness testing is a hardness testing technique that was developed by frederik knoop and his colleadues at the national Bureau of standard.

How does it work?.

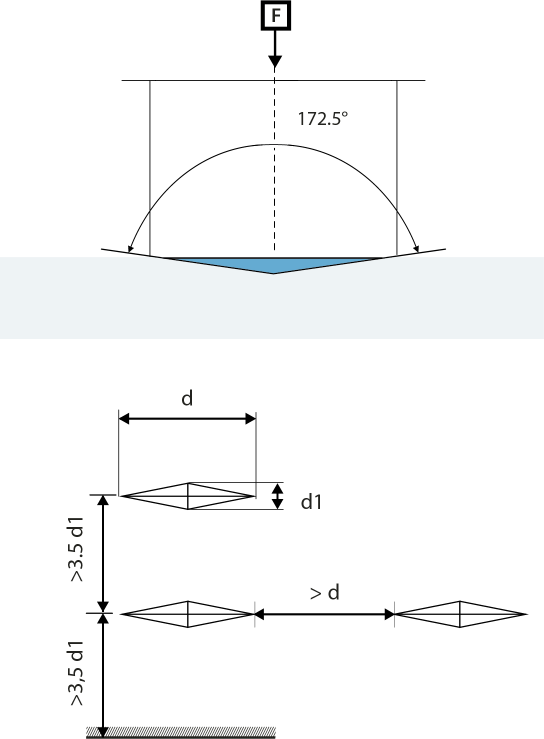

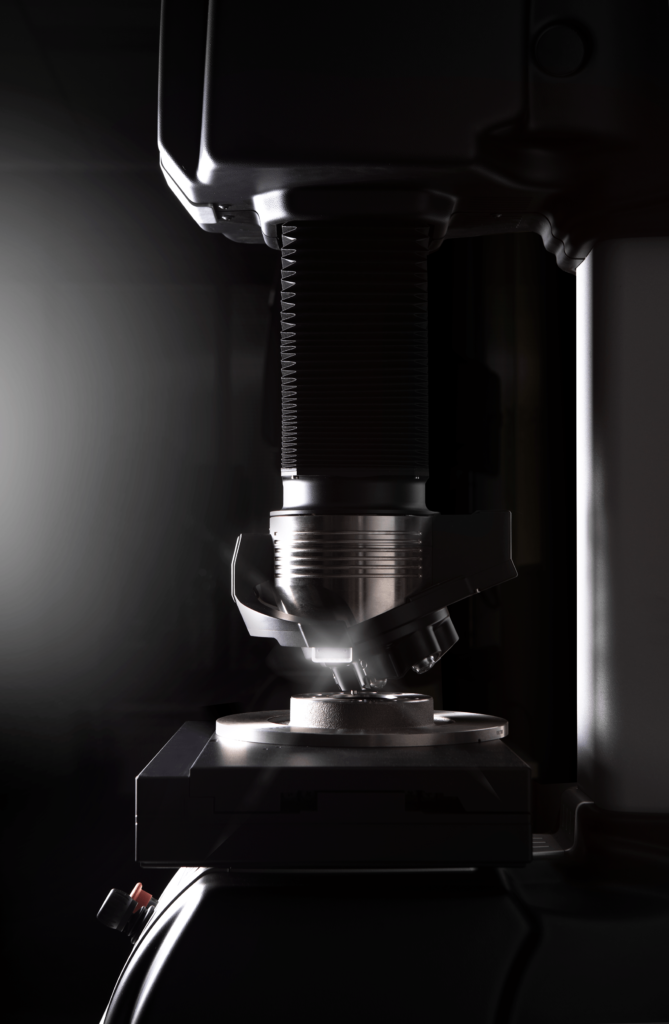

This technique is used mostly with very thin sheets and brittle objects using a pyramidal diamond shaped indenter which is pressed into the test material for a defined time and the indentation made is measured using a microscope. It is used with objects which only requires a small indentation so as to take the measurements. The measurement is then converted to a hardness number using a chart. It is important to make sure that the surface of the material being tested is well prepared by making sure that it is smooth so as to make a good measurement shape and above all to make sure that the material is held in place by the indenter.

Why consider using this test?

In this test only as a small sample of the material is required since it is used mostly for very thin materials which unfortunately requires time to prepare making it a bit time consuming. When choosing this type of hardness test it is important to give the right specification so that you may not confuse it with the Vickers hardness testing which has a few similar characteristics.